●General Information

Wavy and guard belt conveyor is a new type of bulk materials continuous conveying equipment, can be widely used in coal, chemical industry, electric power, building materials, metallurgy, light industry, grain industry, port, etc. It has the general belt conveyor advantages of simple structure, reliable operation, convenient maintenance, but also has the characteristics such as large dip angle convey, compact structure, covers less area, so it is big dip Angle (vertical) transportation ideal equipment.

●Structure Features

Wavy and guard belt consists of machine belt, baffle and clapboard. The appearance of the machine is same as the ordinary conveyor belt, but with greater lateral stiffness. The undulating belt is to make the conveyor belt can bypass roller and convex, concave arc section, to meet the requirements of transmission line. Wave shape has the sine wave, square wave and w-shaped wave, etc. Belt between the two and guards on the machine, the clapboard is set according to certain distance. Clapboard according to the different cross section can be divided into T, C, and TC. T is suitable for Angle β≤ 40 °; C is suitable for Angle β> 40 ° and the material better liquidity situation; TC is suitable for Angle β> 40 °, material big viscosity, particle size is bigger.

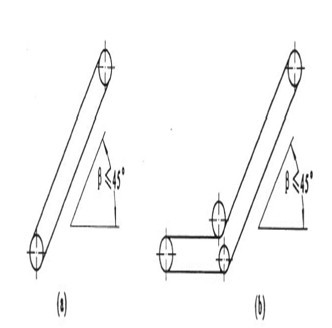

●Type Instruction

●Main Performance Parameters

1. Belt Width (mm): 500, 650, 800.

2. Guard height (mm): 80, 100, 125, 160, and 200.

3. Distance between Clapboards (mm): 126, 252, 378.

4. Belt Speed: 0.8, 1.00, 1.25, 1.60, 2.00, 2.50.

5. Dip Angle β (°): 30, 35, 40, 45, 50, 55, 60, 65, 70, and 75.

6. Convey Capability (M3/H): 5.6~430.

7. Power(KW): 1.5,2.2,3.0,4.0,5.5,7.5,11.0,15.0,18.5,22.0.

●Choice of model

The main problem could be settled by the guard belt conveyor is to choose the belt width, the guard height H, the distance between clapboards ts, belt speed V, drive power P according to the material properties and the required delivery capability. And customer can choose the delivery dip angle α and machine type base on produce process.

The max granularity of conveying material:

Belt Width B | Guard Height H | Distance between Clapboard ts | Dip Angle of Convey machine β | |||||||||

30° | 35° | 40° | 45° | 50° | 55° | 60° | 65° | 70° | 75° | |||

500 | 80 | 126 | 80 | 80 | 80 | 80 | 80 | 60 | 60 | 60 | 60 | 60 |

252 | 100 | 100 | 80 | 80 | 80 | 60 | 60 | 60 | 60 | 60 | ||

100 | 126 | 80 | 80 | 80 | 80 | 80 | 60 | 60 | 60 | 60 | 60 | |

252 | 120 | 120 | 100 | 120 | 120 | 75 | 75 | 75 | 75 | 75 | ||

125 | 252 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | |

378 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | ||

650 | 100 | 126 | 80 | 80 | 80 | 80 | 80 | 60 | 60 | 60 | 60 | 60 |

252 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | ||

125 | 252 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | |

378 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | ||

160 | 252 | 160 | 160 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | |

378 | 180 | 180 | 140 | 140 | 140 | 110 | 110 | 110 | 110 | 110 | ||

800 | 125 | 252 | 160 | 160 | 160 | 160 | 160 | 130 | 130 | 130 | 130 | 130 |

378 | 150 | 150 | 120 | 120 | 120 | 90 | 90 | 90 | 90 | 90 | ||

160 | 252 | 160 | 160 | 160 | 160 | 160 | 130 | 130 | 130 | 130 | 130 | |

378 | 220 | 220 | 180 | 180 | 180 | 150 | 150 | 150 | 150 | 150 | ||

200 | 252 | 160 | 160 | 160 | 160 | 160 | 130 | 130 | 130 | 130 | 130 | |

378 | 250 | 250 | 220 | 220 | 220 | 190 | 190 | 190 | 190 | 190 | ||

The Belt Speed Table

Guard Height H(mm) | ≤125 | ≤200 | |||||

Dip Angle of Conveyor β | ≤35 | ≤50 | ≤75° | ≤35° | ≤50 | ≤75° | |

Granularity(mm) | ≤100 | 2.00 | 1.60 | 1.25 | 2.50 | 1.60 | 1.25 |

≤160 | 1.60 | 1.25 | 1.00 | 2.00 | 1.60 | 1.25 | |

≤200 | - | - | - | 1.60 | 1.00 | 0. 80 | |

The Bulk Density of Material use in common ρ:

Material Density | Coal | Coal Cinder | Coke | Mn ore | Pyrite | rich iron ore | poor iron ore | iron ore concentrate | dolomite |

Loose Density | 0.8-1.0 | 0.6-0.9 | 0.5-0.7 | 1.7-1.8 | 2 | 2.5 | 2 | 1.6-2.5 | 1.2-1.6 |

Material Density | Fritter Lime Stone | Sinter Mixture | Sand | Broken Stone and Gravel | Dry and Soft Soil | Salt | Powder calcium oxide | Powder calcium oxide | Lime Stone |

Loose Density | 1.2-1.5 | 1.6 | 1.6 | 1.8 | 1.2 | 0.8-1.2 | 0.55 | 0.55 | 1.6-2.0 |

Delivery Ability Q:

The delivery capability’s unit is m3/h,multiply by the stock density (t/m3) is t/h。

Belt Width | Guard Belt | Clapboard | Speed V | Dip Angle of Conveyor β | |||||||||

B | Width H | Gap ts(mm) | (m/s) | 30° | 35° | 40° | 45° | 50° | 55° | 60° | 65° | 70° | 75° |

(mm) | (mm) | Delivery Capability Q(m3/h) | |||||||||||

500 | 80 | 126 | 0.8 | 28 | 25.6 | 22.5 | 20 | 18.4 | 16.8 | 15.2 | 13.6 | 12 | 11.2 |

1 | 35 | 32 | 28 | 25 | 23 | 21 | 19 | 17 | 15 | 14 | |||

1.25 | 43.75 | 40 | 35 | 31.25 | 28.75 | 26.25 | 23.75 | 21.25 | 18.75 | 17.5 | |||

1.6 | 56 | 51.2 | 44.8 | 40 | 36.8 | 33.6 | 30.4 | 27.2 | 24.8 | 22.4 | |||

2 | 70 | 64 | 56 | 50 | 46 | 42 | 38 | 34 | 30 | 28 | |||

2.5 | 87.5 | 80 | 70 | 62.5 | 57.5 | 52.5 | 47.5 | 42.5 | 37.5 | ||||

252 | 0.8 | 15.2 | 12.8 | 11.2 | 10.4 | 8.8 | 8 | 7.2 | 6,4 | 6 | 5.6 | ||

1 | 19 | 16 | 14 | 13 | 11 | 10 | 9 | 8 | 7.5 | 7 | |||

0.25 | 23.75 | 20 | 17.5 | 16.25 | 13.75 | 12.5 | 11.25 | 10 | 9.375 | 8.75 | |||

1.6 | 30.4 | 25.6 | 22.4 | 20.8 | 17.6 | 16 | 14.4 | 12.8 | 12 | 11.2 | |||

2 | 38 | 32 | 28 | 26 | 22 | 20 | 18 | 16 | 15 | 14 | |||

2.5 | 47.5 | 40 | 35 | 32.5 | 27.5 | 25 | 22.5 | 20 | 18.75 | 17.5 | |||

100 | 126 | 0.8 | 41.6 | 39.2 | 36 | 32.8 | 30.4 | 27.2 | 24.8 | 22.4 | 20 | 18,4 | |

1 | 52 | 49 | 45 | 41 | 38 | 34 | 31 | 28 | 25 | 23 | |||

1.25 | 65 | 61.25 | 56.25 | 51.25 | 47.5 | 42.5 | 38.75 | 35 | 31.25 | 28.75 | |||

1.6 | 83.2 | 78.4 | 72 | 65.6 | 60.8 | 54.4 | 49.2 | 44.8 | 40 | 36.8 | |||

2 | 104 | 98 | 90 | 82 | 76 | 68 | 62 | 56 | 50 | 46 | |||

2.5 | 130 | 122.5 | 112.5 | 102.5 | 95 | 85 | 77.5 | 70 | 62.5 | 57.5 | |||

252 | 0.8 | 24.8 | 21.6 | 19.2 | 16.8 | 15.2 | 13.6 | 12 | 11.2 | 9.6 | 8.8 | ||

1 | 31 | 27 | 24 | 21 | 19 | 17 | 15 | 14 | 12 | 11 | |||

1.25 | 38.75 | 33.75 | 30 | 26.25 | 23.75 | 21.25 | 18.75 | 17.5 | 15 | 13.75 | |||

1.6 | 49.6 | 43.2 | 38.4 | 336 | 30.4 | 27.2 | 24.8 | 22.4 | 19.2 | 17.6 | |||

2 | 62 | 54 | 48 | 42 | 38 | 34 | 30 | 28 | 24 | 22 | |||

2.5 | 77.5 | 76.5 | 60 | 52.5 | 47.5 | 42.5 | 37.5 | 35 | 30 | 27.5 | |||

125 | 252 | 0.8 | 36.8 | 32 | 28 | 24.8 | 22.4 | 20 | 18.4 | 16.8 | 15.2 | 13.6 | |

1 | 46 | 40 | 35 | 31 | 28 | 25 | 23 | 21 | 19 | 17 | |||

1.25 | 57.5 | 50 | 43.75 | 38.75 | 35 | 31.25 | 28.75 | 26.25 | 23.75 | 21.25 | |||

1.6 | 73.6 | 64 | 56 | 49.6 | 44.8 | 40 | 36.8 | 33.6 | 30.4 | 27.2 | |||

2 | 92 | 80 | 70 | 62 | 56 | 50 | 46 | 42 | 38 | 34 | |||

2.5 | 115 | 100 | 87.5 | 77.5 | 70 | 62.5 | 57.5 | 53.5 | 47.5 | 42.5 | |||

378 | 0.8 | 24.8 | 21.8 | 18.4 | 16.8 | 15.2 | 13.6 | 12 | 11.2 | 10.4 | 8.8 | ||

1 | 31 | 27 | 23 | 21 | 19 | 17 | 15 | 14 | 13 | 11 | |||

1.25 | 38.75 | 33.75 | 28.75 | 26.25 | 23.75 | 21.25 | 18.75 | 17.5 | 16.25 | 13.75 | |||

1.6 | 49.6 | 43.2 | 36.8 | 33.6 | 30,4 | 27.2 | 24.8 | 22.4 | 20.8 | 17.6 | |||

2 | 62 | 54 | 46 | 42 | 38 | 34 | 30 | 28 | 26 | 22 | |||

2.5 | 77.5 | 67.5 | 57.5 | 53.5 | 47.5 | 42.5 | 37.5 | 35 | 32.5 | 27.5 | |||

650 | 100 | 126 | 0.8 | 60 | 56 | 52 | 47.2 | 42.4 | 39.2 | 352 | 32 | 28.8 | 25.6 |

1 | 75 | 70 | 65 | 59 | 54 | 49 | 44 | 40 | 36 | 32 | |||

1.25 | 93.75 | 87.5 | 81.25 | 73.7 | 67.5 | 61.25 | 55 | 50 | 45 | 40 | |||

1.6 | 120 | 112 | 104 | 94.4 | 86.4 | 78.4 | 70.4 | 64 | 57.6 | 51.2 | |||

2 | 150 | 140 | 130 | 118 | 108 | 98 | 88 | 80 | 72 | 64 | |||

2.5 | 187.5 | 175 | 162.5 | 147.4 | 135 | 122.5 | 110 | 100 | 90 | 80 | |||

252 | 0.8 | 35.2 | 30.4 | 27.2 | 24 | 21.6 | 19.2 | 17.6 | 16 | 14.4 | 12.8 | ||

1 | 44 | 38 | 34 | 30 | 27 | 24 | 22 | 20 | 18 | 16 | |||

1.25 | 55 | 47.5 | 42.5 | 37.5 | 33.7 | 30 | 27.5 | 25 | 22.5 | 20 | |||

1.6 | 70.4 | 54.4 | 54.4 | 48 | 43.2 | 38.4 | 35.2 | 32 | 28.8 | 25.6 | |||

2 | 88 | 76 | 68 | 60 | 54 | 48 | 44 | 40 | 36 | 32 | |||

2.5 | 110 | 95 | 85 | 75 | 67.4 | 60 | 55 | 50 | 45 | 40 | |||

125 | 252 | 0.8 | 52.8 | 45.6 | 40 | 36 | 32 | 28.8 | 26.4 | 24 | 21.6 | 19.2 | |

1 | 66 | 57 | 50 | 45 | 40 | 36 | 33 | 30 | 27 | 24 | |||

1.25 | 82.5 | 71.2 | 62.5 | 56.2 | 50 | 45 | 41,2 | 37.5 | 33.75 | 30 | |||

1.6 | 105.6 | 91.2 | 80 | 72 | 64 | 57.6 | 52.8 | 48 | 43.2 | 38.4 | |||

2 | 132 | 114 | 100 | 90 | 80 | 72 | 66 | 60 | 54 | 48 | |||

2.5 | 165 | 142.4 | 125 | 112.4 | 100 | 90 | 82.4 | 75 | 67.5 | 60 | |||

378 | 0.8 | 35.2 | 30.4 | 27.2 | 24 | 21.6 | 19.2 | 17.6 | 16 | 14.4 | 12.8 | ||

1 | 44 | 38 | 34 | 30 | 27 | 24 | 22 | 20 | 18 | 18 | |||

1.25 | 55 | 47.5 | 42.5 | 37.5 | 33.7 | 30 | 27.5 | 25 | 22.5 | 20 | |||

1.6 | 70.4 | 60.8 | 54.4 | 48 | 43.2 | 38.4 | 35.2 | 32 | 28.8 | 25.6 | |||

2 | 88 | 76 | 68 | 60 | 54 | 48 | 44 | 40 | 36 | 36 | |||

2.5 | 110 | 95 | 85 | 75 | 67.4 | 60 | 55 | 50 | 45 | 40 | |||

160 | 252 | 0.8 | 68.8 | 62.4 | 55.2 | 49.6 | 44.8 | 40 | 36 | 32.8 | 28.6 | 26.8 | |

1 | 86 | 78 | 69 | 62 | 56 | 50 | 45 | 41 | 37 | 33.5 | |||

1.25 | 107.5 | 97.5 | 66.2 | 77.5 | 70 | 62.5 | 56.25 | 51.25 | 46.25 | 41.88 | |||

1.6 | 137.6 | 124.8 | 110.4 | 99.2 | 89.6 | 80 | 72 | 65.6 | 59.2 | 53.6 | |||

2 | 172 | 156 | 138 | 124 | 112 | 100 | 90 | 82 | 74 | 67 | |||

2.5 | 215 | 195 | 172.5 | 155 | 140 | 125 | 112.5 | 102.5 | 92.5 | 83.7 | |||

378 | 0.8 | 48 | 41.6 | 36.8 | 32.8 | 29.6 | 26.4 | 24 | 21.6 | 20 | 17.6 | ||

1 | 60 | 52 | 46 | 41 | 37 | 33 | 30 | 27 | 25 | 22 | |||

1.25 | 75 | 65 | 57.5 | 51.2 | 46.2 | 41.2 | 37.5 | 33.7 | 31.2 | 27.5 | |||

1.6 | 96 | 83.2 | 73.6 | 65.6 | 59.2 | 52.8 | 48 | 43.2 | 40 | 35.2 | |||

2 | 120 | 104 | 92 | 82 | 74 | 66 | 60 | 54 | 50 | 44 | |||

2.5 | 150 | 130 | 115 | 102.5 | 92.5 | 82.5 | 75 | 67.5 | 62.5 | 55 | |||

800 | 125 | 252 | 0.8 | 68.8 | 60 | 52.8 | 47.2 | 42.3 | 37.6 | 34.4 | 31.2 | 28 | 24.8 |

1 | 86 | 75 | 66 | 59 | 53 | 47 | 43 | 39 | 35 | 31 | |||

1.25 | 107.5 | 93.75 | 82.5 | 73.75 | 66.25 | 58.75 | 53.75 | 48.75 | 43.75 | 38.75 | |||

1.6 | 137.6 | 120 | 105.6 | 94.4 | 84.6 | 75.2 | 68.8 | 62.4 | 56 | 49.6 | |||

2 | 152 | 150 | 132 | 118 | 106 | 94 | 86 | 78 | 70 | 62 | |||

2.5 | 215 | 187.5 | 165 | 147.5 | 132.5 | 117.5 | 107.5 | 97.5 | 87.5 | 77.5 | |||

800 | 125 | 378 | 0.8 | 45.6 | 40 | 35.2 | 31.2 | 28 | 25.6 | 23.2 | 20.8 | 18.4 | 16.8 |

1 | 57 | 50 | 44 | 39 | 35 | 32 | 29 | 26 | 23 | 21 | |||

1.25 | 71.25 | 62.5 | 55 | 48.75 | 43.75 | 40 | 36.25 | 32.5 | 28.75 | 26.25 | |||

1.6 | 91.2 | 80 | 70.4 | 62.4 | 56 | 51.2 | 46.4 | 41.6 | 36.8 | 33.6 | |||

2 | 114 | 100 | 88 | 78 | 70 | 64 | 58 | 52 | 46 | 42 | |||

2.5 | 142 | 125 | 110 | 97.5 | 87.5 | 80 | 72.5 | 65 | 57.5 | 52.5 | |||

160 | 252 | 0.8 | 93.6 | 84.8 | 75.2 | 67.2 | 60 | 54.4 | 49.6 | 44.6 | 40 | 36 | |

1 | 117 | 106 | 94 | 84 | 75 | 68 | 62 | 56 | 50 | 45 | |||

1.25 | 146.25 | 132.5 | 117.5 | 105 | 93.75 | 85 | 77.5 | 70 | 64 | 56.25 | |||

1.6 | 187.2 | 169.6 | 150.4 | 134.4 | 120 | 108.8 | 99.2 | 89.6 | 80 | 72 | |||

2 | 234 | 212 | 188 | 168 | 150 | 136 | 124 | 112 | 100 | 90 | |||

2.5 | 292.5 | 265 | 235 | 210 | 150 | 170 | 155 | 140 | 130.4 | 122.5 | |||

378 | 0.8 | 65.6 | 56.8 | 50.3 | 44.8 | 40 | 36 | 32.8 | 28.6 | 26.4 | 24 | ||

1 | 82 | 71 | 63 | 56 | 50 | 45 | 41 | 37 | 33 | 30 | |||

1.25 | 102.5 | 88,75 | 78.75 | 70 | 62.5 | 56.25 | 51.25 | 46.25 | 41.25 | 37.5 | |||

1.6 | 131.2 | 113.6 | 100.6 | 89.6 | 80 | 72 | 65.6 | 59.2 | 52.8 | 48 | |||

2 | 164 | 142 | 126 | 112 | 100 | 90 | 82 | 74 | 66 | 60 | |||

2.5 | 205 | 177.5 | 157.7 | 140 | 125 | 112.5 | 102.5 | 92.5 | 82.5 | 75 | |||

200 | 252 | 0.8 | 137.6 | 128 | 119.2 | 109.6 | 100 | 89.6 | 81.6 | 73.6 | 664 | 59.2 | |

1 | 172 | 160 | 149 | 137 | 125 | 112 | 102 | 92 | 83 | 73 | |||

1.25 | 215 | 200 | 186.25 | 171.2 | 156.2 | 140 | 127.5 | 115 | 103.7 | 92.5 | |||

1.6 | 275.2 | 256 | 238.4 | 219.2 | 200 | 179.2 | 163.2 | 147.2 | 132,8 | 118.4 | |||

2 | 344 | 320 | 298 | 274 | 250 | 224 | 204 | 184 | 166 | 148 | |||

2.5 | 430 | 400 | 372.5 | 342.5 | 312.5 | 280 | 255 | 230 | 207.5 | 185 | |||

378 | 0.8 | 107.2 | 94.48 | 3.2 | 73.6 | 66.4 | 60 | 54.4 | 48.8 | 44 | 40 | ||

1 | 134 | 94.4 | 83.2 | 73.6 | 66.4 | 75 | 68 | 61 | 55 | 50 | |||

1.25 | 167.5 | 147.5 | 130 | 115 | 103.7 | 93.75 | 85 | 76.25 | 68.75 | 62.5 | |||

1.6 | 214.4 | 188.81 | 66.4 | 147.2 | 132.6 | 120 | 108.8 | 97.6 | 88 | 80 | |||

2 | 268 | 236 | 208 | 184 | 166 | 150 | 136 | 122 | 110 | 100 | |||

2.5 | 335 | 295 | 260 | 2.3 | 207.5 | 187.5 | 170 | 152.5 | 137.5 | 125 | |||

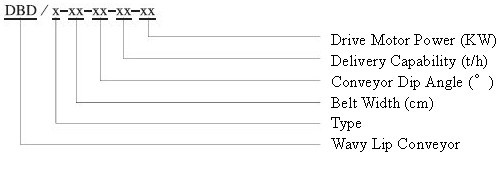

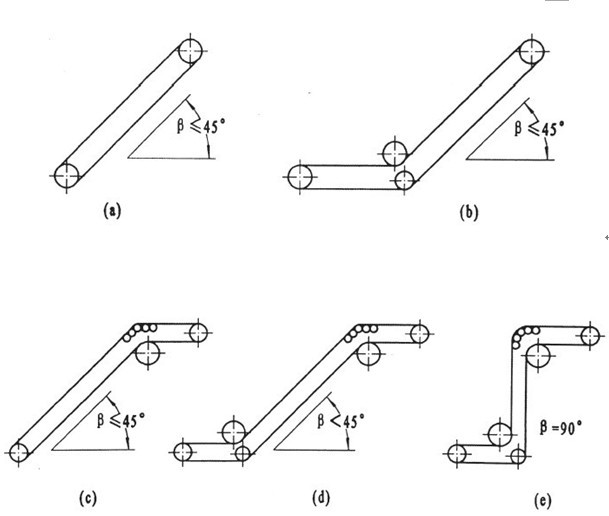

The basic form of whole arrangement:

●Install Instruction

1. Install order: Mark the central line--Install rack--Install downside carrier roller and turnabout drum-Set conveyor’s belt under downside carrier roller-Install upside carrier roller--Install tension device, transmission drum, drive device--Conveyor belt connect-Tensioning belt--Install cleaner, belt hold back, feed channel and casing, etc..

2. All of the drum, roller, and drive device shall be flexible to roll after installation. Buffer carrier roller should guarantee the pretesting force of a spring.

3. When connecting conveyer belt, tensioning drum should be put in the front position, and try to tighten belt.

4. When installing self-aligning carrier roller, block roller wheel should locate behind carrier roller in the belt running direction.

5. When installing drive device should pay attention to make the axis of motor and reducer concentric.

●Testing and Running

1. Speed reducer and electric drum should be enough lubricating oil according to the rules.

2. Please check roller brake’s star wheel installation direction is consistent with non-return direction and the limiting stopper installation of sweeper, belt brake, discharging car sweeper.

3. Please check the electrical signal and the control device connection is correct. Power motor and observe the rotate direction of roller is correct.

4. Please checking conveyor and working part should be no obvious noise during running, each bearing has no abnormal temperature rise, the drum, roller rotation and tighten situation, sweeper cleaning effect.

5. Please check the forward running and inverted running of discharging truck belt and there should no slip after stop. There should no obvious impact when it passes the rail.

6. The convey belt should not has friction with the discharge car when the car is walking.

7. Please adjust the head transmission device if the head belt is off position. Please adjust turnabout drum at the tail or screw tensioning device if the tail part is off position. Please adjust the upside carrier roller and the downside roller if the middle part is off position.

8. Please reduce the material falling height when running so that the reduce impact on the convey belt, and please get rid of the off position, and regular inspection maintenance.

9. Please stop the conveyor as possible as the material discharge is accomplished, and with no-load startup advisable.

●Place order Information

1. Specifying the name of the conveyed material, particle size, bulk density and natural stacking angle, moisture content, temperature and other physical properties.

2. Transmission capacity, transmission speed and conveyor belt specification.

3. The work environment, such as temperature, outdoor, indoor, etc.

4. In the process plan drawing should indicate the elevation of horizontal section, length, hoisting height, angle, elevation of upside horizontal section, length.

5. Whether need the head casing.