●General Information

The existing powder blender mixer is divided into pneumatic and mechanical. And the mechanical Blender Mixer is divided into single shaft and double-shafts. The advantage of mechanical type is mixing evenly and reliably. But the parts serious wear and tear easily and large consumption of unit mix of material. And need the specialized processing set-up. Pneumatic Blender Mixer is divided into air-flowing type and gasification type. It with the characteristics of fast mixing, low powder consumption, small consumption of parts, but the material is affected by the gas short circuit and eddy and boundary effect. And the homogeneity of material is low and also need specialized processing set-up. So the existing blender mixer has its own boundedness in the actual producing process.

The new designed UQJ Pneumatic and Mechanical Combined Type Blender Mixer from our company is concluded the advantage of both pneumatic type and mechanical type. It not only has the characteristics of even mixing of mechanical type but also has the fast mixing, low power consumption and small consumption of parts. Especially there is no need to setup specialized process. It could be installed after small improvements of by-pass of convey equipment. There is a lot of praises from many cement factories.

●Characteristic

1. Reliable and even material mixing. Using overflow structure ensures big quantity of online material mixing.

2. Low power consumption, <0.15Kw/H per cubic meter mixing.

3. Small wear and tear of the equipment, there is no need to change the quick-wear part in a year.

4. Easy processing set-up. No need for special process line. The martial could exit from side or bottom.

5. Large mixing quantity: 50—500m³/h.

6. It is effective to remove the saccharoid (impurity).

●Requirement for the mixing material

1. It must be the powdery material, the fineness ≤15%.

2. Moisture is not greater than 1.5%。

3. The density is under 2*10³kg/m³.

4. No Viscosity.

5. Ensure the measurement's accuracy of feeding material.

●Work Principle

The aerating box with air permeable layer at the bottom of blade stirring silo is equipped with mixer shaft. The roots blower blows the high pressure air into o the aerating box, when the material is fed into the stirring box. Because the gasification effect of aerating box, the material will get fluidization. Then material will be aerating stirred by the blade in the stirring box. Because the outlet of material is upside, the mixed material will overflow from the outlet. The material under the outlet will get agitation with the subsequent material in the stirring box then overflow from the outlet. Because the full fluidization of material in the stirring box and the overflow structure the sacchariod (impurity) will deposit at the bottom of the stirring box. When the mixing machine needs rest, we could clear the saccharoid (impurity) from side of the stirring box's bottom.

●Type and Basic Parameters

1. Pneumatic and mechanical combined type mixer, the type is QJ.

For Example

2. Mixing ability and power consumption list

Type | UQJ500*3500 | UQJ630*3500 | UQJ800*4000 | UQJ500*3500-2 | UQJ630*3500-2 | UQJ800*4000-2 |

Mix Ability m³/h | 30--100 | 50--150 | 100--300 | 50--150 | 100--300 | 200--500 |

Shaft Power KW | 2.2 | 4 | 5.5 | 2*3 | 2*4 | 2*5.5 |

Blower Power KW | 2.2 | 3 | 4 | 4 | 5.5 | 7.5 |

Total Power KW | 4.4 | 7 | 9.5 | 10 | 13.5 | 18.5 |

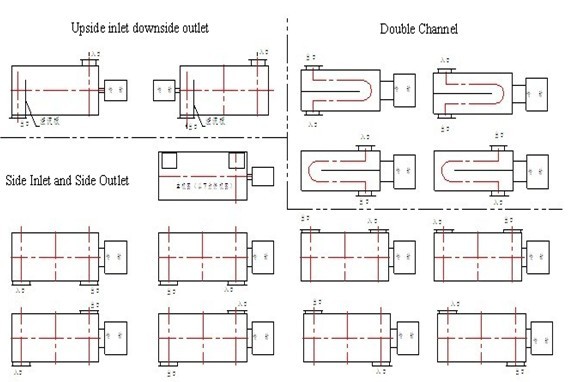

3. The processing set-up line of pneumatic and mechanical combined type mixer

4. Pneumatic and mechanical combined type mixer's external size

External Size Type | L | L1 | L2 | H | H1 | B | B1 | B2 | ØC |

UQJ500*3500 | 4430 | 3050 | 3880 | 1400 | 1100 | 1300 | --- | 515 | Ø89 |

UQJ630*3500 | 5030 | 3550 | 3880 | 1520 | 1220 | 1400 | --- | 610 | Ø108 |

UQJ800*4000 | 5700 | 4050 | 4380 | 1800 | 1500 | 1500 | --- | 715 | Ø133 |

UQJ500*3000-2 | 4430 | 3050 | 3580 | 1400 | 1100 | 1750 | 960 | 480 | Ø89 |

UQJ630*3500-2 | 5030 | 3550 | 3880 | 1520 | 1220 | 1900 | 1180 | 480 | Ø108 |

UQJ800*4000-2 | 5700 | 4050 | 4380 | 1800 | 1500 | 2000 | 1400 | 500 | Ø133 |

●Ordering Specification

1. Please choose the equipment according to the mixing quantity.

2. Please choose the installation position by the external size of the equipment.

3. Please choose the processing set-up line according the mixing material yard.

4. Please choose the material inlet and outlet structure and gearing according to the mixing processing set-up line.

5. Please choose the impurity window and pipe inlet position according to the real work position.

●Installation

1. Please choose the installation position according to real work position and processing set-up.

2. Please fasten the equipment tightly to the foundation horizontally.

3. The joint of the material inlet and outlet should be smoothly and no material blocked.

4. Flanges of material inlet and outlet, gate, aerating box should be sealed by the gasket and fastened tightly.

5. The inlet pipe should match the blower's rate and fluency.

6. Roots blower and accessories should be installed by the installation instruction.

7. Please follow the principle of waterproof, rain-proof, moisture proof when you are installing the equipment.

●Application and Maintenance

1. The use of roots blower should follow the installation and maintenance instruction. Full the lubricating oil and silencer, check valve, pressure gage should in the right position and with right connection. The safety valve should be adjusted to the safety range.

2. The air duct and material inlet and outlet pipe, the flange and the mixer should ensure air-proof, no ash leaking, handle the question in time.

3. Turn on the roots blower first and 5-10 min later, turn on the mixer.

4. Please observe the change of electricity and pressure gage. If it is over rated-value, please handle in time.

5. Please adjust the angle of blade according to the mixing quantity ensure the satisfaction of mixing material.

6. Please add and change lubricating oil at regular time.

7. Please check and clean the impurity at the bottom of the stirring box and please clean it on time.

8. Please check if there is water or affected by damp before turning the equipment on. Please clean in time when you find there is solidification and harden in case of burning the motor or equipment.